Subscribe to the newsletter

Use of AI in logistics cost optimization

Cost optimization is as important in logistics as it is in other industries. Digitization and the use of modern technologies can not only reduce costs, but also process orders faster and increase sales. Customers are already used to instant service and expect their orders to arrive within a few working days. To meet the ever-increasing expectations of customers, companies must boldly invest in innovative technologies such as artificial intelligence (AI).

Logistics companies generate billions of gigabytes of data every day. With the help of AI, we can use it to make better business decisions and perform everyday tasks more effectively. Artificial intelligence enables, among other things, optimal route planning for the correct allocation of goods and vehicles and the reduction of customer waiting time for service.

How does the use of AI in logistics look like in practice?

- Automation of warehouses

One of the most common applications of artificial intelligence is the transformation of activities performed daily in warehouses (inverotry, product allocation, analysis of product information). How exactly is this done?

By using AI, we can predict the demand for certain products. Based on the estimated quantities, the company sends the required items to the appropriate warehouses. This significantly reduces transportation costs, as a situation where goods are under-delivered and need to be replenished cannot occur.

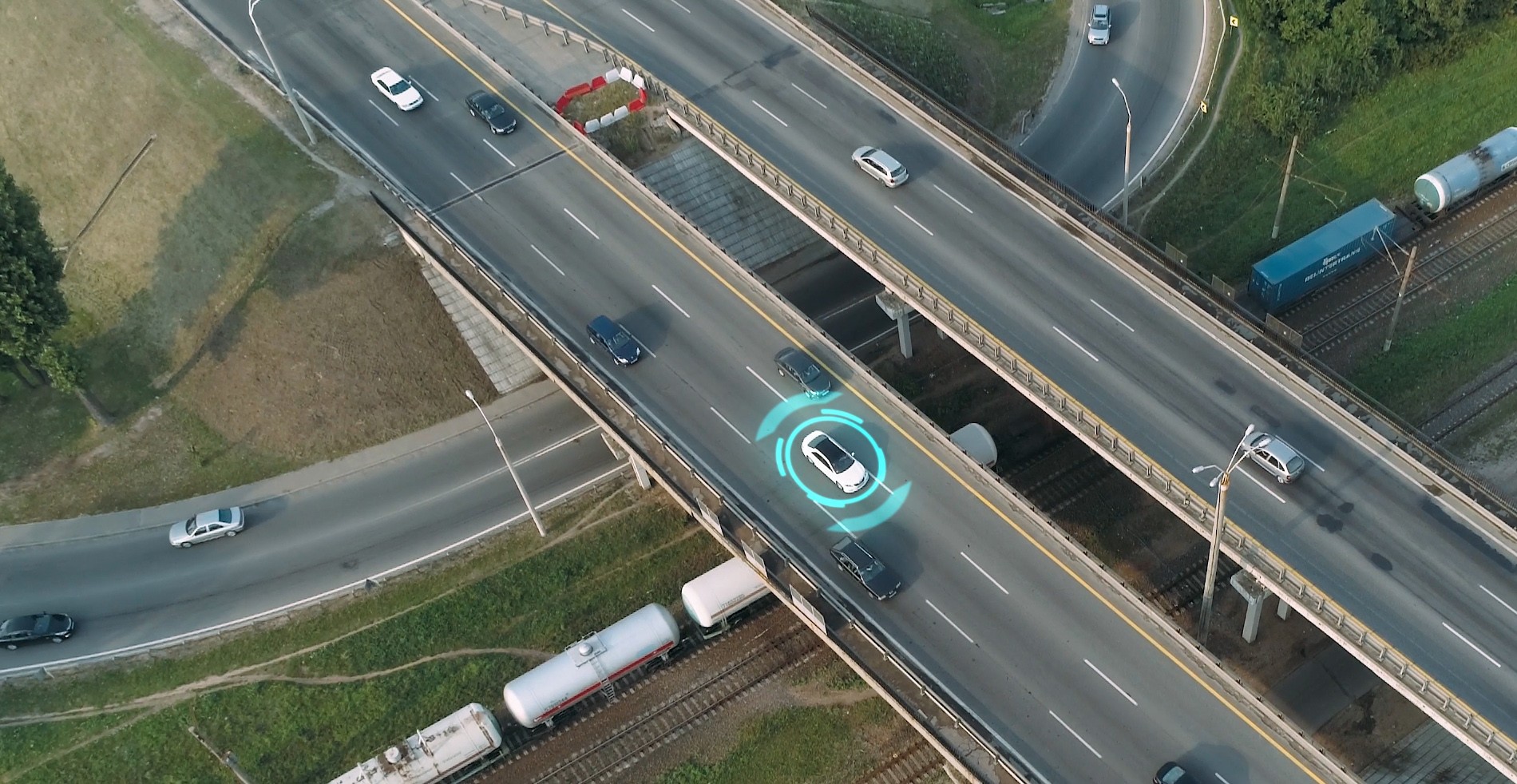

- Autonomous vehicles

One area of logistics that benefits most from artificial intelligence is transportation. We are already able to optimize routes and thus reduce overall transportation costs. But that's not all AI can do. The technology makes it possible to drive vehicles on autopilot without a human being behind the wheel. The use of this innovation in trucks and other transport vehicles would shorten driving times, reduce fuel consumption and avoid the consequences of human error.

Despite the benefits that the introduction of autonomous vehicles could bring, many governments are against the use of this solution on a larger scale. A common demand is that there should be a driver in such a vehicle who can additionally monitor the traffic situation and take appropriate action in case of danger. However, it is possible that as this technology improves, we will see more autonomous vehicles on the roads in the future.

- Internal operation of the company

Artificial intelligence can also be used in the internal activities of logistics companies. The technology allows the automation of complex routine tasks (preparation of accounts, analysis). This leads to greater accuracy of results and significant time savings, which in turn increases the efficiency of the company and reduces costs.

- Demand anticipation and better customer service

To serve customers efficiently, companies must know their resources and be able to predict the approximate quantities of goods they will need. If they lose control of inventory and demand exceeds supply, the company faces additional costs and dissatisfaction from potential buyers.

The use of artificial intelligence allows for a more accurate estimation of demand than when done by humans. The technology takes into account various factors and analyzes how they affect each other. Such information facilitates inventory management and shortens order fulfillment time, which positively impacts overall customer satisfaction with your business.

As you can see, artificial intelligence can be used at different levels of logistics processes. It allows you to efficiently manage the warehouse and stock it with the right amount of products, as well as optimize transportation and improve customer service. AI technology is indispensable for companies that want not only to survive in the market, but above all to develop dynamically and win over the competition by optimizing internal processes and increasing customer satisfaction. So, if you have not invested in artificial intelligence-related solutions yet, it's high time to think about it!